Volkswagen, like other European automakers, has faced major challenges in this transition period to electrification. Plans that were made with the anticipation of substantial EV growth have had to be adjusted, while the onslaught of lower-priced EVs from China has also forced a new look at product development and strategies in order to be competitive.

The German automaker has now adopted an ambitious 3-stage plan as follows:

CATCH UP: Strengthen competitiveness by optimising cost structures and extending the existing model portfolio in a targeted way.

ATTACK: Introduce 9 new models by 2027 including the production version of the ID. 2all for less than €25,000 and the entry-level electric car for about €20,000.

LEAD: as the technologically leading brand in the volume segment.

Addressing employees at the factory in Wolfsburg, Thomas Schafer, CEO of the Volkswagen Passenger Cars brand, presented plans for the future of the core brand. “With the results of the negotiations in December, we have embarked on the largest future plan in the history of Volkswagen. We are now following an ambitious course with a view to ensuring that we reach the targets we have jointly agreed. This will be a key step in making electro-mobility attractive for everyone – the clear goal of our brand,” said Schafer.

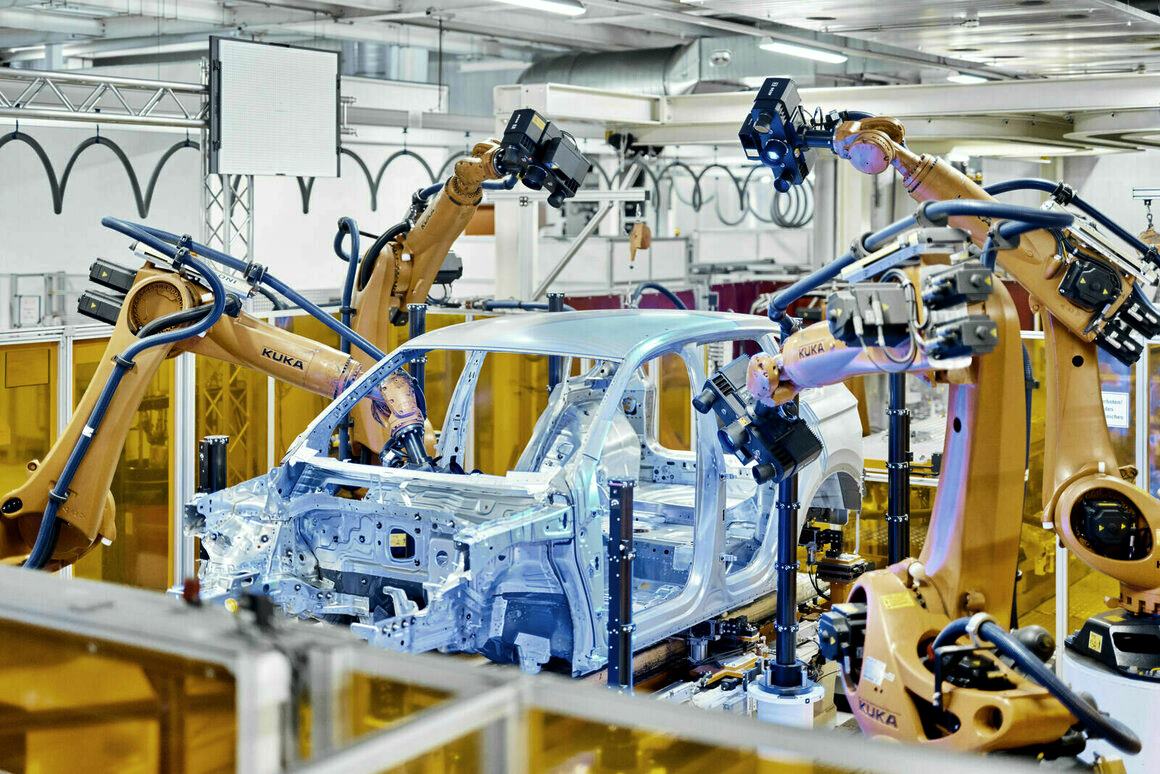

Low-cost entry-level mobility in the electric era will be one of the cornerstones of the brand’s future plan. In this respect, there will be a model family which includes compact all-electric vehicles based on the new stage in the evolution of the modular electric drive (MEB) platform. The first new model will be the production version of the ID. 2all, which will be presented in public as a showcar next month.

The all-new model is to reach dealerships in 2026 as Volkswagen’s first all-electric small car – at a base price of less than €25,000 (around RM115,000), possibly around €20,000 (RM92,000).

Future of Wolfsburg plant

At the works meeting, Schafer emphasized that the Wolfsburg plant – one of the largest vehicle manufacturing plants in the world – would remain the heart of the Volkswagen brand in the electric age: “The Wolfsburg plant has a clear perspective for the future. The agreed relocation of the Golf to Mexico will free up space for advanced technologies. In Hall 54, new production procedures will be introduced. We intend to produce the electric Golf successor on the new SSP platform there, as well as the high-volume electric T-Roc. This way, we will be making Wolfsburg the capital of our new all-electric compact class.”

![Volkswagen ID.2all EV showcar [2025] Volkswagen ID.2all EV showcar [2025]](https://www.motaauto.com/wp-content/uploads/2025/02/Volkswagen-ID.2all-EV-showcar-2025-696x392.jpg)