Ten years ago, when the quest to stretch each litre of liquid fuel was still ongoing, the idea of the ‘1-litre car’ was pursued. It didn’t refer to the engine displacement (there were already cars with 1-litre engines in the market) but rather that 1 litre of fuel could take a vehicle 100 kms.

Some European companies took up the challenge and Volkswagen beat that target with its XL-1 achieving 0.9 litre/100 kms. It was the world’s most fuel-efficient production car as the carmaker actually made 250 units and sold 200 of them to the public.

Still aiming for longer range

Fast forward to 2023 and the pursuit of fuel efficiency with engines that use petrol or diesel is no longer the challenge. Now it is the range that a battery electric vehicle (BEV) can go – running only on electricity. And just as with combustion engines, the number is steadily extending as technologies improve.

Range on a full battery pack is, like fuel consumption, dependent on various factors – how you drive, where you drive, how much braking you do, many variables. Generally, the industry has a few standards or test cycles that are used so that there is a basis of comparison.

Using 1,000 miles/1,600 kms as the target may be challenging but if 1,000 kms as the target, it almost certainly will be reached during this decade. BEV technology, particularly in batteries, has been advancing very quickly. Unfortunately, it is not like computer technology where, following Moore’s Law, the number of transistors in an integrated circuit has doubled every 2 years or so, increasing processing capabilities.

From 250 kms to over 750 kms

Just 10 years ago, the best range was around 250 kms (155 miles); today, the Mercedes-Benz EQS has a claim of between 700 and 750 kms (434 – 465 miles). The German carmaker’s Vision EQXX has recorded 1,000+ kms across Europe but that’s a prototype.

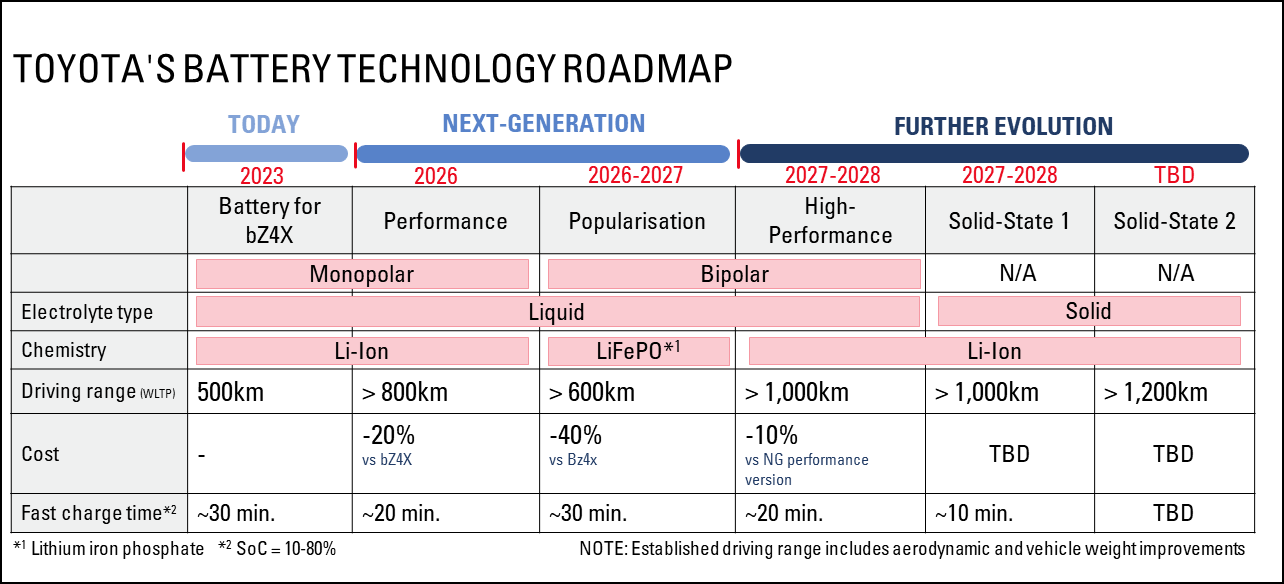

Toyota expects to hit 1,000 kms by 2027 or 2028 as begins using more advanced battery technology. At the moment, its best range is 500 kms with the bZ4X but its next generation of BEVs from 2026 will have Performance lithium-ion batteries which will have increased cruising range of over 800 kms.

Lower-cost batteries

At the same time, the company is also working hard to bring costs down and compared to the current bZ4X, the cost of the next generation battery should be 20% lower. More affordable BEVs will be key to faster switching from combustion vehicles, Toyota is also working on lower-cost batteries.

Its ‘Popularisation Battery’ concept uses bipolar technology that the carmaker pioneered and confirmed with its NiMh hybrid electric vehicle batteries, combined with inexpensive lithium iron phosphate (LiFePO) as the core material.

These batteries will not offer as much range as the Performance Battery, but at 600+ kms, there will still be a 20% increase in range (compared to bZ4X). They can be 40% cheaper than current batteries and take 10 minutes longer for recharging from 10% to 80% than the Performance battery’s 20 minutes.

Reducing battery height

Besides battery technology, other areas of the vehicle such as aerodynamics and weight will also contribute to going further. Here, the height of the battery pack, which is typically housed under the vehicle’s floor, influences overall vehicle height. Too high and it then has a disproportionate multiplied effect on aerodynamic drag and consequently on the potential range.

Therefore, reducing the height of the battery pack will allow the vehicle height to also be lower, with positive implications on aerodynamic efficiency. Having to overcome less drag will allow the vehicle to go further.

Future battery development

By 2027 or 2028, Toyota expects to have pushed battery development to be able to achieve 1,000+ kms. This will still use liquid electrolyte, just as what has been used up till today. However, during the same period, we are likely to see the introduction of an entirely new generation of batteries. These are known solid-state batteries (SSBs) and uses a solid electrolyte instead of liquid electrolytes.

Just as the invention of the transistor in 1947 accelerated the semiconductor industry to enter the electronic age, SSBs are seen as the energy storage devices for future BEVs and could be in use before the end of the decade.

Long seen as a potential game-changer for BEVs, Toyota has made a technological breakthrough in its quest to improve the durability of such batteries. The SSBs have a solid electrolyte, allowing for faster movement of ions and a greater tolerance of high voltages and temperatures. They also have greater energy density so more power can be stored in a smaller form, and they are suitable for rapid charging/discharging.

Shorter battery life has been one of the issues of SSBs which Toyota researchers have been working to overcome. Recent technological advancements have overcome this challenge and the company has switched its focus to putting SSBs into mass production. Of course, before that can be done, a lot of testing is needed to ensure that Toyota’s high standards of durability and reliability are met.

At the same time, the cost has to be brought down (it is very expensive at this time) before commercialisation can be considered. Once available, BEVs can be expected to go beyond 1,000 kms and even over 1,200 kms, and a 10% to 80% recharge should take around 10 minutes. By then, battery chargers should also have advanced further to speed things up as well.

Offering various battery options

“We will need various options for batteries, just like we have different variations of engines. It is important to offer battery solutions compatible with a variety of models and customer needs,” said Takero Kato, President of a BEV Factory that began operations recently. This upholds Toyota’s multi-pathway approach to carbon-neutrality by offering customers choices so no one is left behind.