Proton, like many automakers around the world, has extensive R&D facilities to develop new models. Many of these facilities were set up during the 1990s and the biggest would be the test track which allows different types of testing of prototype vehicles as part of development programs of future models or improvements to current ones.

When the Proton factory was originally built in 1984, it already had a large test track – the first of its kind in the Malaysian auto industry (and probably in Southeast Asia). It occupied the entire length of one side of the factory site with two long straights and loops at each end. The loops were flat so drivers had to reduce their speeds as they went around the curves.

Upgraded in 1993

Following the opening of the R&D Centre in 1993, Proton began to upgrade the existing test-track to a more comprehensive one which would allow not only final testing of completed vehicles but also prototypes. As Mitsubishi Motors was then the technical partner, the test-track at the Okazaki complex in Japan was used as a reference.

The new test-track was on the existing one except that it had a larger area in between the two straights where additional test courses would be incorporated. It took 2 years to complete and was operational in 1995.

42-degree banks

Apart from the larger area (220,000 sq. metres or 54.3 acres), the prominent features were the two banks at either end of the 1,800-metre long straights with 3 lanes. The banking allows the drivers to maintain high speeds as they loop around. The angle of each bank is 42 degrees, which is about the same as many other automakers’ test-tracks.

The steepest in the world is at the Mercedes-Benz track in Stuttgart, Germany which has a section that is 90 degrees. Yes, that is literally a vertical wall and a very high speed is required to go around it. Mercedes-Benz says that, theoretically, a car can travel over 200 km/h but this is not done as the g-forces generated would not be tolerable by the driver. The maximum they do is 200 km/h and even at that speed, the driver will experience a weight factor of 3.1 (three times actual weight).

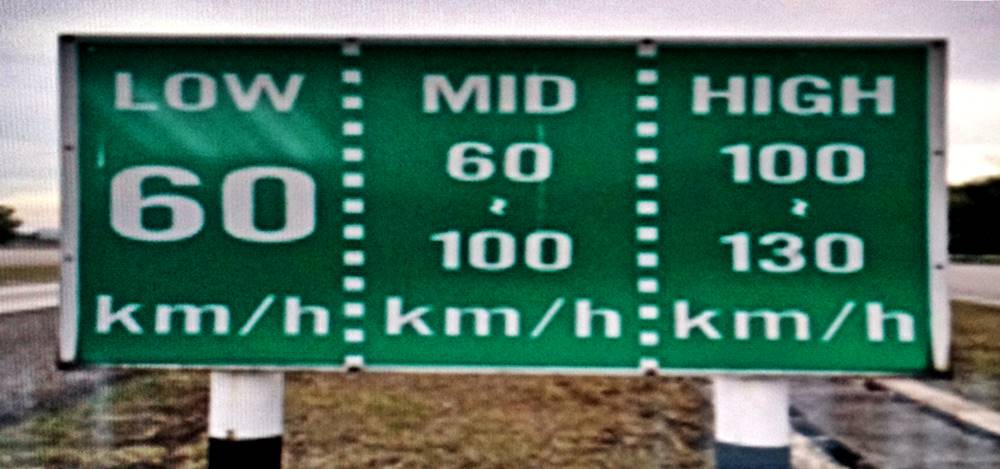

The banking on Proton’s test-track has a maximum speed limit of 130 km/h on the uppermost of 3 lanes. Along the middle lane, which is not as much as 42 degrees, the speed is 60 km/h to 100 km/h. The third lane is flat and the speed limit is 60 km/h.

For many who drive on the track the first time and speed around the banking, it is quite a thrill. And what’s even more exciting is that it is possible, when travelling at high speeds, to not have to steer the vehicle as the g-forces will keep it ‘stuck’ to the track while the curvature guides the vehicle around.

Of course, this is usually done by an experienced driver. In fact, at the Mercedes-Benz track, visitors who travel around the banking in a bus get shocked when the driver suddenly takes his hands off the steering wheel and holds them in the air!

Safety is a top priority

The same speeds that apply on the banking generally apply to the straights, although slightly higher speeds are allowed in certain conditions. However, as at all test-tracks around the world, safety is a top priority and everyone driving must follow the procedures. Even media who have visited the track many times must sit through a briefing before every test-drive to ensure they are clear on the safety procedures.

24-hour, all-weather testing

With its own test-track, Proton’s test-drivers can conduct testing at all times of the day and in all weather conditions. The track is not visible to the public so secrecy for prototype models is assured, although there is still testing done on public roads to put prototypes through real-world conditions. The forthcoming e.MAS 7 EV, for example, has been on extensive drives around the country to see how it performs on the varied surfaces of our roads.

Various test courses

Various test courses

Over the years, the track continued to get additional test courses for conducting other types of tests, besides just driving round and round. There are sections with different surfaces (including potholes) to test suspension for ride comfort, twisty sections to test handling, and an area where vehicles go through water and showers.

There is also a section for braking tests to be carried out and a large circular area where steering systems are tested. The track also has a sloped area for testing climbing ability, while a section is allocated for noise tests. These noise level tests follow the ISO standards and are requirements in certain markets, so Proton has to ensure its vehicles meet the standards.

Test-track in Tg. Malim in future

It is likely that when Proton fully relocates to its manufacturing complex Tg. Malim in Perak after 2027, the closure of the original complex in Shah Alam will also mean that the test-track will no longer be used.

There is already a large oval test-track at the Tg. Malim site with some facilities although Proton doesn’t say anything about it at this time. It has two straights, one about 1.2 kms long and the other about 500 metres, with loops at either end (but no banking). When all operations are centralised there, the test-track would probably be upgraded with more advanced testing facilities.