Since the 1990s, automakers have used the shared platform approach for their vehicles, which reduces development costs as one platform can be used for a range of models. The common parts that are in the platform also mean better economies of scale which also drives costs down.

![Stellantis STLA Medium Platform [2023]](https://www.motaauto.com/wp-content/uploads/2023/07/Stellantis-STLA-Medium-Platform-2023-2.png)

Prior to the 1990s, many automakers had over a dozen platforms, each specific to a model. This was steadily reduced to just a handful which would be used for sedans, pick-up trucks, MPVs and SUVs, with the platform dimensions varied to suit the body size. In more recent years, platforms dedicated to EVs have also been developed, allowing for more optimised placement of battery packs and motors.

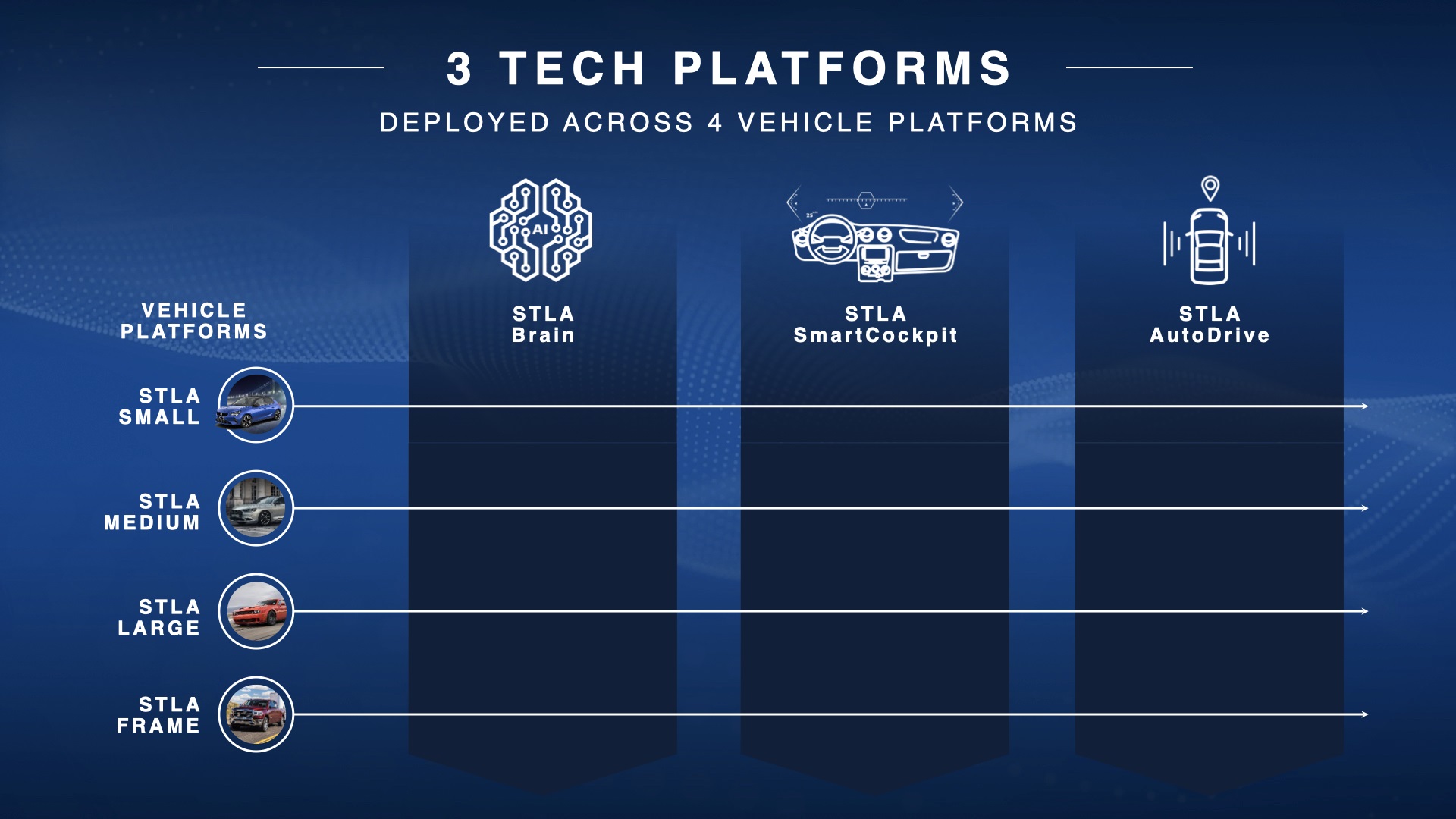

Stellantis has a platform strategy which consists of four STLA platforms that will be used by its many brands for different types of models. To date, it has shown the STLA Medium and STLA Large platforms which are for models in the C and D segments globally.

Now, the group has unveiled the STLA Frame platform, a BEV-native but also multi-energy platform engineered for full-size body-on-chassis frame pick-up trucks, light commercial vehicles and SUVs. STLA Frame vehicles will initially be offered with choice of fully electric or range-extender electric (REEV) drivetrains. Where needed, the same platform can also accommodate internal combustion engine, hybrid and even hydrogen propulsion systems.

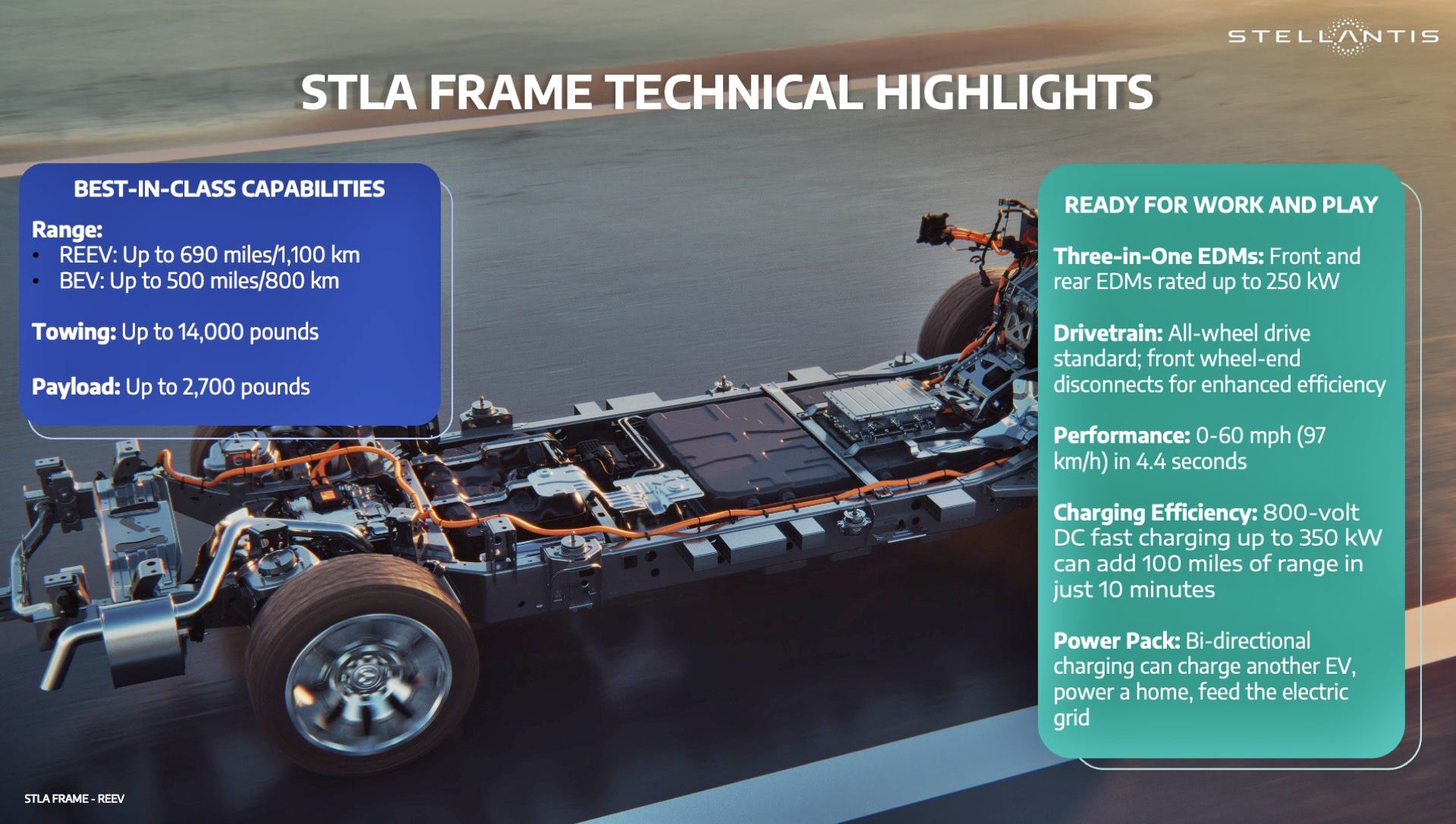

The STLA Frame is built using advanced, high-strength steel for improved durability and rigidity with less weight. The widened centre section houses the battery pack, with reinforced frame rails that protect the battery in the event of a side impact. A full-length belly pan reduces aerodynamic drag to help maximize driving range, promoting efficiency without sacrificing performance.

The platform, when using a battery electric drivetrain, is designed to give range of up to 800 kms. Front and rear electric motors will generate up to 250 kW of power and provide all-wheel drive. Flexible suspension designs, including air suspension, offer an optimized ride for diverse driving conditions and loading scenarios.

With 800V architecture and DC fast charging up to 350 kW, 160 kms of range can be added within 10 minutes. The REEV battery can also be fast-charged when required, getting up to 90 kms of range in 10 minutes with 400V DC fast charging at up to 175 kW.

The REEV drivetrain, which combines a battery, front and rear electric drive modules, on-board generator and internal combustion engine, allows drivers to go further while transporting heavy loads. With no direct mechanical path from the engine to the wheels, the generator powers the motors to propel the vehicle and recharges the battery as needed. The high torque of the motors offers the advantages of an EV and a range of up to 1,100 kms is projected.

“Like STLA Medium and STLA Large, STLA Frame combines an unprecedented range with new levels of capability and performance to offer best-in-class range, payload and towing for our customers who need reliable and powerful trucks and SUVs, to haul their families or power their businesses,” said Stellantis CEO Carlos Tavares.

“With full EV and extended-range EV tech coming soon, we’re bringing ‘no compromise’ solutions to buyers who may be hesitant on trying their first electric vehicle. We’re proud of this engineering marvel and look forward to seeing it come to life in our upcoming product blitz on Jeep and Ram,” he said.

Stellantis outlines plans for ASEAN region, to invest RM2 billion