Perodua may seem to have been quiet where its electric vehicle is concerned but the Malaysian automaker has been hard at work with the development program, with the aim of launching its first EV model within a year.

Since 2023, the progress it has made has been shown in various stages as its knowledge and experience was building up. It is important to note that Perodua is not working with its technical partner and shareholder, Daihatsu Motor, on this model or even to co-develop it. The automaker has been building up its expertise in-house, complemented by the considerable product development skills it has gained since being established in 1993.

Of course, it is not going to develop 100% of the skills needed and like other automakers, it also works with companies that are specialists in certain fields. For instance, it is known that Bufori Malaysia, a 38-year old manufacturer of niche luxury cars, for bodywork expertise.

Owning the EV technology

However, for the core systems and technologies, Perodua will develop in-house which means that ultimately, it will own the technologies rather than depend on a technical partner. That would certainly be in the national interest and Perodua is, after all, a Malaysian automaker.

A further benefit is that having developed the technologies itself, it will be thoroughly familiar with its product. It is like the difference between building your own computer and just buying a ready-made one from the shop. If you have built it yourself, you know how the cables are connected and where each component is, so if you have to repair or make changes, you can do it yourself.

Second prototype

At the Malaysia Auto Show in May 2024, Perodua showed a prototype model – the emo-I – and many details of its drivetrain and systems. This week, at KLIMS 2024, the automaker is showing a running prototype of the emo-II (’emo’ stands for Electric Motion Online) which it says is quite close to what the production model will look like.

![Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/12/Perodua-emo-II-EV-2024-13.jpg)

However, like most concept cars, some of the futuristic details may not be feasible for the production model. To ‘Malaysianise’ the design, there are some songket-inspired elements around the bodywork. The overall size is 2 to 3% different from what will be in showrooms. The emo-II (which is unlikely to be the showroom name) will be a separate model line and not a variant of the Myvi, as was speculated earlier.

![Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/12/Perodua-emo-II-EV-2024-6.jpg)

Before the model is launched, there will be a third version – referred to as ‘Episode 3 – which will probably be a production-ready prototype. If MARii (Malaysia Automotive Robotics and IoT Institute) holds the Malaysia Auto Show in May, then we might see it there.

![Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/12/Perodua-emo-II-EV-2024-9.jpg)

![Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/12/Perodua-emo-II-EV-2024-10.jpg)

The drivetrain is obviously completed and now under testing as the emo-II could be driven onto the stage. The few details we were able to obtain are that there will be a single motor driving the front wheels and output will be around 118 kW (160 ps)/220 Nm.

![Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/05/Perodua-EMO-1-EV-powertrain-2024-scaled.jpg)

![Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/12/Perodua-emo-II-EV-2024-7.jpg)

400-km range targeted

The engineers are targeting a range of 400 kms with the battery provided by CATL, the largest battery manufacturer in the world which supplies to many other automakers. Charging time will be within 31 minutes with high-speed DC supply and like other EVs, many hours if using the slower AC supply.

![Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/12/Perodua-emo-II-EV-2024-11.jpg)

Space-optimised interior

The interior has good space for passengers and the designers have clearly made full use of the advantages of a platform with a fully electric powertrain. Just as the switch to front-wheel drive liberated space in the cabin, EVs also offer more space due to the absence of large (and heavy) components like the combustion engine, exhaust system, etc. The battery, which used to take up space in the boot in early EVs, is now placed under the floor between the front and rear wheels so it doesn’t intrude into the cabin.

![Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/12/Perodua-emo-II-EV-2024-1.jpg)

![Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/12/Perodua-emo-II-EV-2024-2.jpg)

The dashboard and other futuristic displays may just be ideas that the interior designers have at this time (though it is likely that the design has been approved and ‘frozen’ by now). It’s hard to say how close what we see in this emo-II will be to what buyers get. The curved instrument panel may be adopted but will there be a centre display like most EVs today? Will Perodua’s designers adopt a touchscreen approach or still have physical controls, which is what many motorists prefer.

![Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/12/Perodua-emo-II-EV-2024-4.jpg)

![Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/12/Perodua-emo-II-EV-2024-3.jpg)

![Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/12/Perodua-emo-II-EV-2024-5.jpg)

Typically, with concept cars, designers have a lot of freedom since the parts may not go into production, so with things like 3D-printing, complex forms can be made. But when it comes to actually manufacturing the car, then it is a different matter as cost and practical considerations have to take priority.

![Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/12/Perodua-emo-II-EV-2024-12.jpg)

The potential demand is a crucial factor that determines whether a model should be produced, and how much it will cost. If the potential numbers are not high enough, then the price target might be difficult to meet so it’s a balancing act. In Perodua’s case, their mission has always been to provide Malaysians with affordable cars and that includes EVs.

To be priced below RM100,000

The technology may still be expensive as it is still in its infancy, so the effort has been to find ways to reduce costs. Perodua aims to offer the emo-II at not more than RM100,000 and this is based on potential demand which it says could be up to 10,000 units.

Dedicated EV production facility

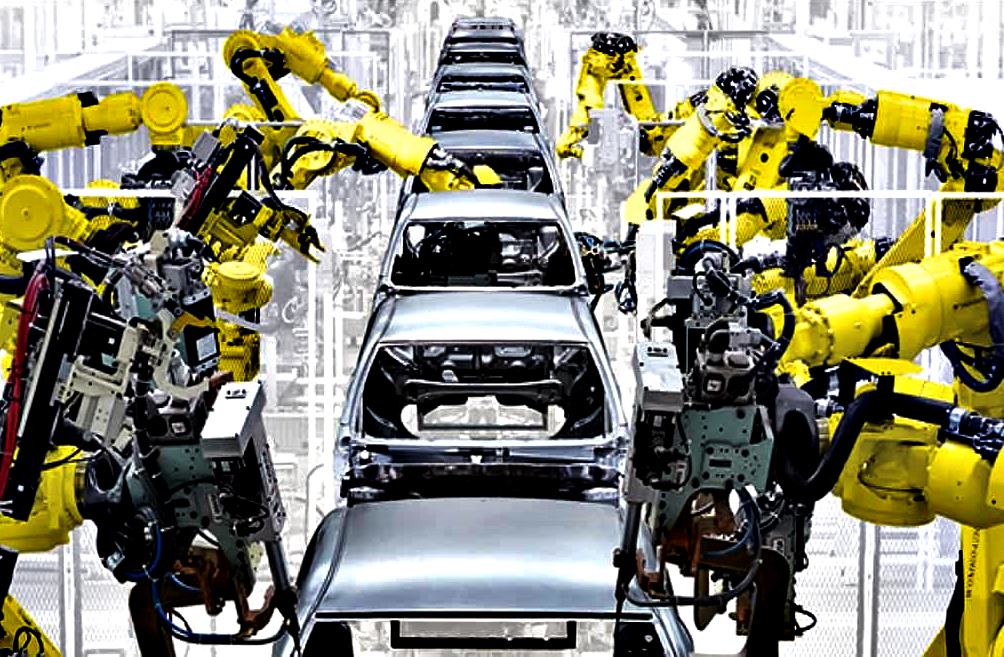

Because the emo-II is a different car from anything Perodua has ever built and also because its initial volume will be low, it cannot be made in either of the existing factories at the manufacturing complex. Having gone beyond the 300,000-unit level, Perodua’s processes cannot cater for smaller volumes as productivity will be affected.

It has obtained a manufacturing licence to produce the new EV and is now constructing a new facility at the complex. The initial output will be 500 units a month, allowing the workers to become familiar with the processes and also ironing out any issues before pushing the volume higher. In this way, the finished product can be of the high quality that the brand has built a reputation for.

Given the proven reliability of Perodua vehicles and also their good aftersales support, many Malaysians may be persuaded to buy its first EV. After all, it is going to be an EV developed by Malaysians for Malaysians and made in Malaysia. That would certainly boost EV adoption and support the government’s push for the switch.

Perodua unveils first working EV prototype at Malaysia Autoshow

![Perodua emo-II EV [2024] Perodua emo-II EV [2024]](https://www.motaauto.com/wp-content/uploads/2024/12/Perodua-emo-II-EV-2024-15-696x421.jpg)