In 2026, Proton will be producing its first EVs at its manufacturing complex in Tanjung Malim, Perak. This will commence upon completion of its first dedicated EV production plant which is scheduled at the end of this year.

The RM82 million plant is the first phase of the EV production plan which will see up to 20,000 vehicles being produced annually. While only one EV model – the e.MAS 7 – has been launched, there are more models in the pipeline which will utilise the Geely Group’s Global Modular Architecture (GMA) platform.

Proton’s production of EV models in Tanjung Malim is in line with the automaker’s commitment to fulfil the Malaysian government’s EV industrialisation plan and subsequently stimulate EV sales traction in Malaysia. The move is guided by related directions spelled out in key policies, namely the New Industrial Master Plan, National Automotive Policy 2020, Low Carbon Mobility Blueprint, and New Energy Transition Roadmap.

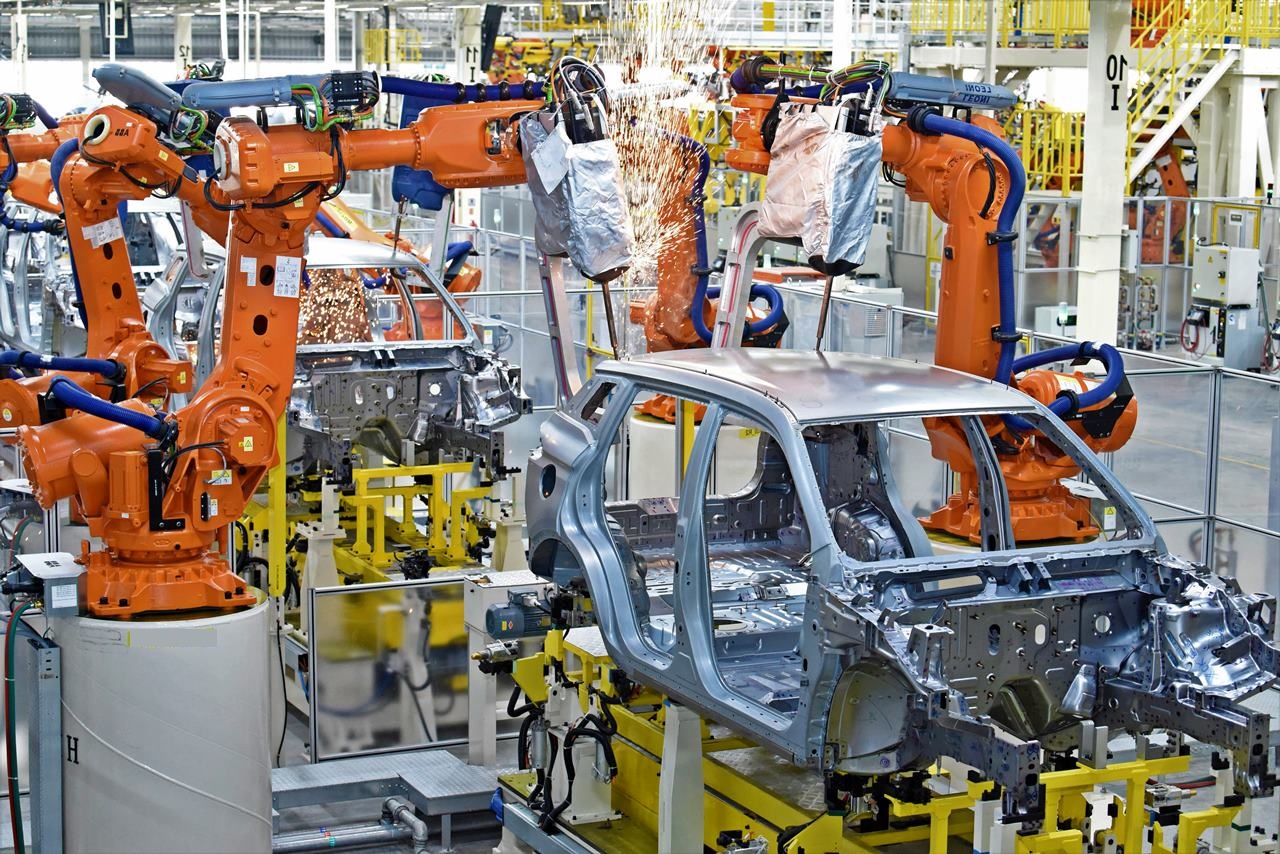

Smart manufacturing technologies

Befitting a new purpose-built facility that caters to the production of New Energy Vehicles (NEV), a range of solutions under the umbrella term of ‘smart manufacturing technologies’ are deployed to ensure the delivery of high quality products with maximum efficiently and minimal impact to the environment. The production line will have a high degree of automation in its operations by leveraging on robotics, cloud-based plant management, industrial Internet-of-Things (IoT) and technologies synonymous with IR 4.0.

Despite the utilisation of the latest intelligent production operations, Proton estimates the new plant will lead to the creation of over 200 new jobs, specialising in EV industrialisation and technical services, for the local community.

This is before the knock-on effect to the Automotive High-Tech Valley (AHTV) vendor community is calculated as it ramps up operations to supply value-added parts to critical to assembly operations.

Up to 45,000 units annually

Proton also has plans in place for the second phase of its new production plant in anticipation of growing acceptance and demand for EVs from customers. This will ramp up production capacity to 45,000 units, by which time all of Proton’s manufacturing operations will be consolidated in the AHTV.

“Proton began making its transition to become an automaker offering ICE (internal combustion engine) and NEV models when we established PRO-NET to sell electric vehicles from smart in 2023, before launching the Proton e.MAS 7 last year in 2024. Over this period, we have accumulated a lot of experience in all areas regarding these vehicles and the needs of their customers, so today we take another step to realising our dream of manufacturing and developing EV models in Malaysia. The vehicles produced here at this new plant will serve our domestic customers and export market while becoming a catalyst to driving the growth of the EV market,” said Dr. Li Chunrong, CEO of Proton, at the commencement event this morning.

“Once completed, this new factory will focus on producing the Proton e.MAS 7 as well as future NEV offerings as Proton expands its model range. Ultimately, we hope our success will establish a modern and capable automotive ecosystem to encourage more automakers to consider Malaysia and AHTV as a regional base for EVs,” he added.

Click here to know more about the Proton e.MAS 7.