With the way global warming is making days hotter, travelling in a car is more preferable than being out in the open. However, that’s because the car has an air-conditioner to provide cool air and make the cabin environment comfortable.

The air-conditioner uses energy as it is driven by some engine power; in EVs, energy from the battery pack is used to run the compressor. In both cases, energy is used and if this can be reduced, the energy savings can benefit the motorist.

Nissan has been testing an innovative approach which uses automotive paint to help lower the cabin temperature and thereby reduce energy demand from the engine or battery to run the compressor. Developed in partnership with Radi-Cool, a specialist in radiative cooling products, the paint incorporates metamaterial, synthetic composite materials with structures that exhibit properties not usually found in nature.

The project is part of Nissan’s pursuit of differentiated innovations that empower journeys and to help create a cleaner more sustainable society.

Nissan’s ‘cool paint’ has metamaterial embedded within it which features 2 microstructure particles that react to light. One particle reflects near-infrared rays in the sunlight that would typically cause molecular level vibrations within the resin of traditional paint to produce heat.

The second particle enables the real breakthrough. It creates electromagnetic waves, that counteract the sun’s rays, redirecting the energy away from the vehicle into the atmosphere. Combined, the particles in the experimental paint reduce the transfer of heat into surfaces such as the roof, bonnet, doors and other body panels.

While radiant cooling paint isn’t new, it is typically used for buildings and structures. It’s often very thick, requiring application by a paint roller. Devoid of any clear topcoat, it can leave a chalky residue when touched.

The automotive version developed had to be able to incorporate a clear topcoat, be applied via a spray gun (not a roller), and meet Nissan’s rigorous internal standards for paint quality.

In November 2023, Nissan commenced a 12-month feasibility trial at Tokyo International Air Terminal at Haneda. In collaboration with Japan Airport Terminal Co., Ltd., Radi-Cool Japan, and All Nippon Airways airport service, Nissan’s cool paint was applied to a Nissan NV100 service vehicle operated by the airline’s airport services.

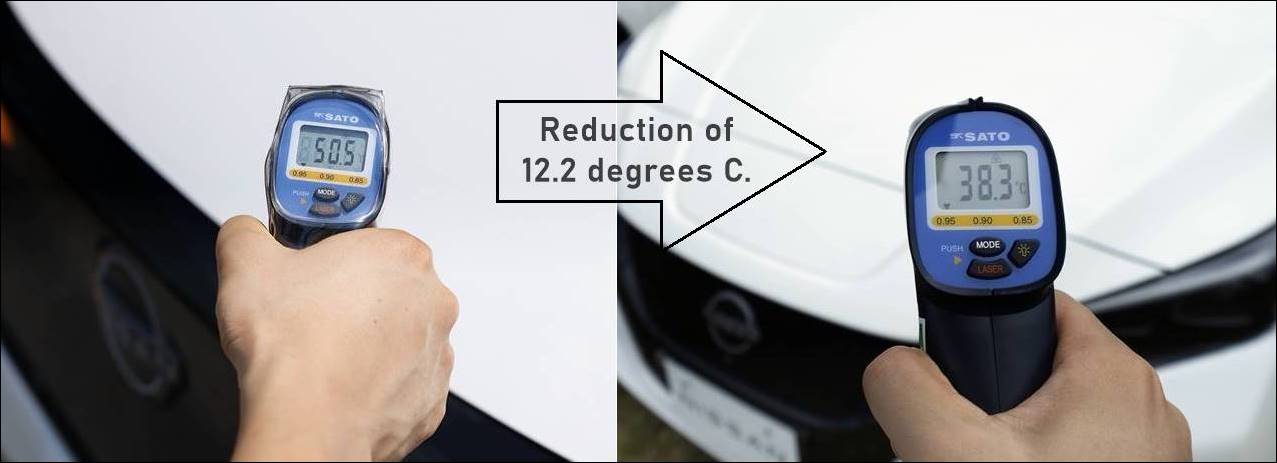

With its large, open tarmac, Haneda airport provided the perfect environment to conduct real-world evaluation of the paint’s performance under an exposed high-temperature environment. Although still in testing phase, the results to date have been impressive.

Parked side-by-side under the sun, a vehicle treated with the special paint has shown yields of up to a 12o C. reduction in exterior surface temperatures and up to 5o C. cooler interior, compared to a vehicle having traditional automotive paint. The paint’s cooling performance is particularly noticeable when a vehicle is parked in the sun for an extended period.

A cooler cabin is not only more pleasant to enter, but also requires less air-conditioning run-time to cool the space to a comfortable temperature. This helps reduce the draw on engine power or, in the case of an EV, draw on the battery. In both powertrains, an improvement in efficiency is expected.

While the testing and development is ongoing, the hope is that such paint can one day be offered for special orders and in a variety of colours. There is strong potential, particularly for light commercial vehicle applications such as vans, trucks and ambulances that spend most of the day out on the road under the sun.

Click here to know more about Nissan vehicles in Malaysia